Some people may think that manufacturing clothes is a simple quest, but the truth is that there is a huge and complex process behind finding the perfect piece of underwear, up to people’s standards of looks, quality, and fit.

Explaining the steps involved in this process is what today’s blog is about, understanding the answers to questions like:

Where does this amazing piece of clothing come from? And why does this one feels more special and is a better fit than other similar ones I have?

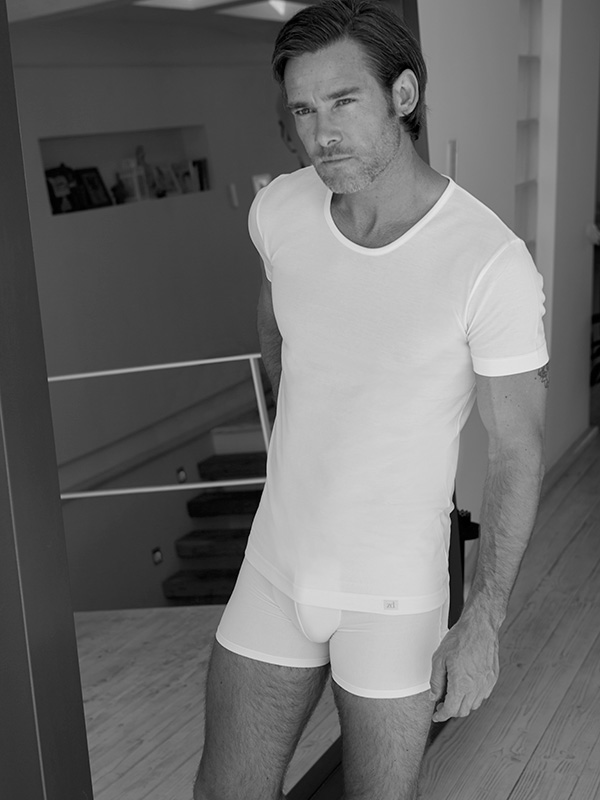

The manufacturing of clothes matters from the very first step of the process. The selection of the fabric has a direct impact on the end result, to the point that the specific cut or design (boxer, briefs or anywhere in the middle, for instance) is relevant only on your body type, but the feeling as “natural, second skin” must the same on everyone. Achieving this only happens when the choice of fabric is made appropriately. And the brand, the company, and the people in the designing team are responsible this decision-making process.

So, here is another thought to get my point across. Have you ever made or eaten paella with ingredients from “alternative” origin (and you can swap paella for whatever other meal you can think of)? In a paella, for my example, when tomatoes are not as juice, garlic is not as fresh, peppers are not as crispy, or seafood is not as flavorful, you might have the “right” ingredients but you will never eat the same paella… A similar concept happens with clothing.

Which is the first step?

In dressmaking and designing, the road to exquisiteness and success starts with fabric selection. Fabrics are made of fibers that are twisted into yarns, and these define the quality of the final outcome. In order to obtain sewing threads of the highest quality, we at ZD select and handpick yarns from noble materials and apply high technology spinning processes. The resulting sewing threads are only turned into suitable fabrics if the knitting process is done by professional hands under trained and certified supervision.

The approved material is then passed on to the dying phase and submitted to other polishing touches. Herein, unless non-aggressive and self-conscious methods are employed, everything accomplished so far could turn useless. We, at ZD Zero Defects, obtain the best fabrics with unique colors and textures not only complying by the regulations in the industry, but taking into account other human and environmental needs. We follow the dying process with care and vigilance.

After that, the resulting fabrics where no error is detected are passed on to the manual cutting. Layers are placed on top of each other until forming and mattress-like surface where patterns of different garments are placed. Pieces are cut by tracing the patterns onto the fabric with a bandsaw. Other pieces are also cut to form the waistband and leg area with another specialized machine that cuts the fabric into slices. From there, it all goes to the sewing workshop.

And then?

Sewing the pieces together is not an easy task due to the elasticity and thinness of the noble material. It requires expert, qualified hands working with care and precision that aim to achieve perfection. Our team of seamstresses keeps this in mind when assembling the parts. The manufacturing process sequence goes through eight stations with distinct machines (overlocking, stitching, embroidering, quilting, etc.). The last step is labeling; this includes specifying the size, care instructions, fiber content, and our identity logo.

All this complex manual routine is handled cautiously, but the most challenging part that marks the difference is ensuring flat seams in all garments. To achieve this, a designated person from the sewing team opens up all the stitches, one by one, with patience and serenity, but we feel the effort is worth it.

At the end, each piece is supervised and taken into the lab to do the final checks. If every test is passed satisfactorily, the garment is ironed, folded, boxed, and ready to enter the marketing phase.

Following the market chain, it will end up on the shelves of your provider of choice. You can then start enjoying its comfort and benefits, and now knowing why.

Reader Interactions